Introduction

The cord bonding job is a integral process in semiconductor production and electronic meeting. It serves as a very important connection between built-in circuits (ICs) and their substrates, allowing electrical signs to waft seamlessly. With the quick enlargement of electronics in a number industries comparable to automobile, aerospace, and clinical devices, know-how the intricacies of cord bonding era has certainly not been greater vital.

In this entire handbook, we can delve into a lot of factors of wire bonding such as its methodologies, appliance, purposes, reliability checks, and long term traits. By the finish of this text, you're going to have a thorough information of the wire bonding manner and its significance in modern day electronics.

What is Wire Bonding?

Wire bonding is a way used to create electrical connections among semiconductor instruments and their applications or substrates utilising first-class wires. The system typically involves two relevant recommendations: ball bonding and wedge bonding. Each procedure has its very own precise purposes relying on points like fabric residences and layout requirements.

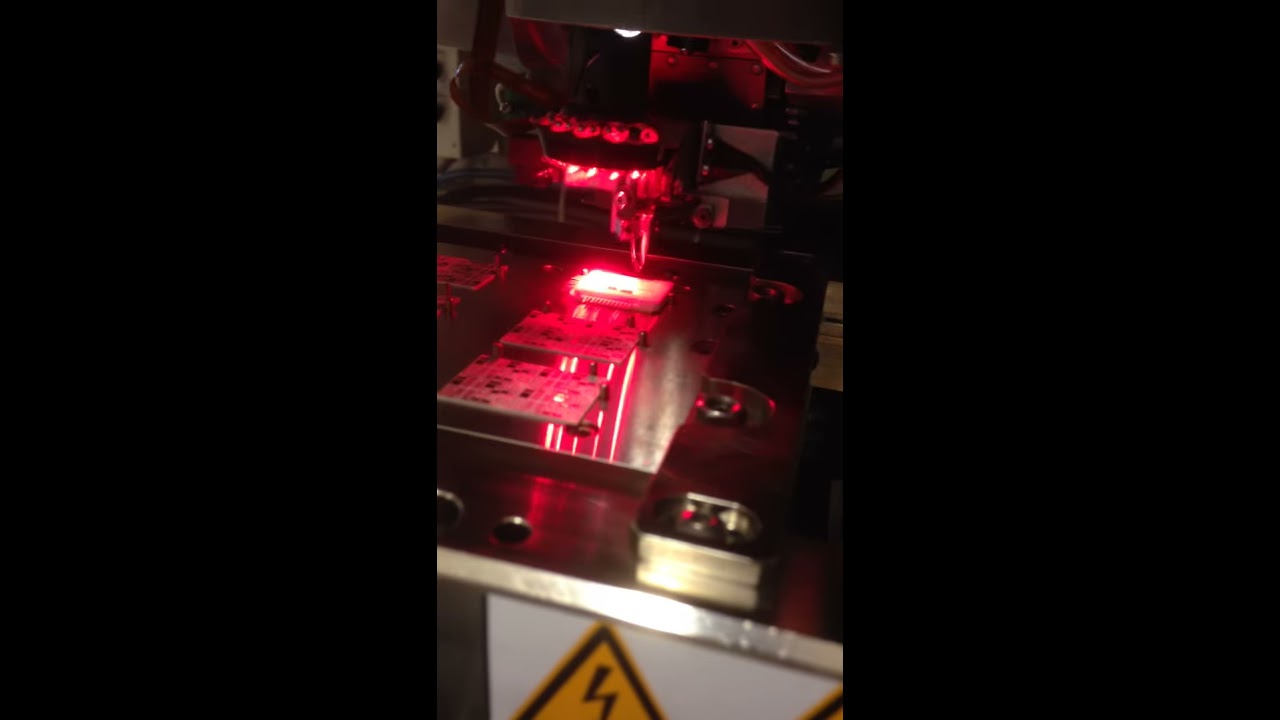

How Wire Bonding Works

Wire bonding employs mechanical stress and heat to variety bonds among metal wires—mostly gold, aluminum, or copper—and pads on silicon chips or other surfaces. The decision of textile many times depends on settlement issues, thermal conductivity, and efficiency specifications.

Understanding the Wire Bonding Process: A Comprehensive Guide

The Importance of Wire Bonding Technology

Wire bonding science plays a pivotal role in making certain official connections within electronic gadgets. As know-how advances towards miniaturization and increased complexity, robust cord bonding options are predominant for high-efficiency applications.

Different Types of Wire Bonding Techniques

Ball Bonding- This process comprises developing a small ball at the cease of a wire by means of melting it with warm beforehand making touch with the bond pad.

- Wedge bonding utilizes a flat software to press the wire in opposition to the substrate with out heating it.

- Ribbon bonding employs broader strips of metal rather then basic circular wires for higher surface location touch.

Wire Bonding Equipment: Key Components

- Wire Bonding Machine: The coronary heart of the operation in which automation takes vicinity. Bonding Capillary Tool: Essential for positioning the wire correctly. Ultrasonic Generator: Supplies ultrasonic strength during selected kinds of bonds.

Wire Bonding Applications Across Industries

Wire bonding reveals use in a range of sectors:

- Automotive Electronics: Ensures official connections in defense techniques. Medical Devices: High reliability is paramount for lifestyles-saving machine. Aerospace: Components must resist excessive circumstances. Consumer Electronics: Mobile devices require compact arrangements.

Wire Bonding Failure Analysis

Understanding expertise failure modes is valuable for improving reliability:

Oxidation Contamination Incomplete Bonds More helpCommon Failures in Wire Bonding

Failures can appear with the aid of bond lifting or heel cracks that compromise connectivity. Identifying those complications early can restrict superb losses down the road.

Wire Bonding Reliability Factors

Reliability is prompted via a couple of causes:

- Environmental controls Material choices Bond power calibration

Quality Control in Wire Bonding

Implementing stringent good quality regulate measures guarantees that every single bond meets market specifications. Techniques like visible inspection or automated bond inspection play vital roles right here.

Cost Implications of Wire Bonding Processes

Understanding wire bonding rates can guide enterprises make informed decisions on manufacturing:

- Material fees (gold vs aluminum) Labor charges associated with handbook as opposed to computerized processes Maintenance expenditures for machinery

Comparative Analysis: Gold vs Aluminum Wire Bonding

| Factor | Gold Wire | Aluminum Wire | |---------------------|---------------------------|-----------------------------| | Cost | Higher | Lower | | Oxidation Resistance | Excellent | Moderate | | Thermal Conductivity | Superior | Good |

Best Practices in Wire Bond Design

Proper layout rules can make stronger reliability:

Bond Strength Considerations

Achieving foremost bond electricity calls for cautious calibration of parameters equivalent to pressure settings for the duration of utility.

Specialized Techniques in Wire Bonding

Advanced concepts include:

Micro Wedge Bonding Thermosonic Ball Bonding Deep Access Wedge BondingThese systems cater to designated demanding situations posed by means of excessive-density designs.

FAQs approximately Wire Bonding

What supplies are more commonly used in wire bonding?

Common materials incorporate gold, aluminum, copper, and silver by means of their stunning conductive homes.

How does environmental control influence cord bonding?

Proper environmental controls mitigate dangers reminiscent of oxidation or infection which could cause failures.

What industries benefit from wire bonding?

Industries like automotive, scientific devices, aerospace, client electronics, and telecommunications all depend on legit cord bonds for function.

How do you function first-rate manipulate assessments all the way through cord bonding?

Quality checks may additionally involve visible inspections, automated testing machines for bond integrity checks (shear exams), and x-ray inspections to discover hidden blunders.

What is ribbon bonding? How does it range from common techniques?

Ribbon bonding makes use of wider strips as opposed to around wires enabling greater surface facet touch which enhances reliability but may well require specialised machine.

Can I customise my wire bonding companies?

Yes! Many providers offer custom treatments tailored to distinctive task necessities inclusive of cloth option and layout requirements.

Conclusion

In conclusion, getting to know the complexities surrounding the twine bonding manner is imperative for everyone worried in semiconductors or electronics production as we speak. From selecting true materials to wisdom the several approaches like ball as opposed to wedge bonding—every single thing contributes vastly to general product functionality and reliability. Embracing improvements although adhering to universal appropriate practices will be sure efficient outcomes throughout countless applications.

By following this entire instruction manual on Understanding the Wire Bonding Process: A Comprehensive Guide you presently have basic insights into optimizing your operations even though declaring high specifications throughout the time of your initiatives!