Introduction

The wire bonding manner is a basic method in semiconductor production and digital assembly. It serves as a principal connection between incorporated circuits (ICs) and their substrates, allowing electric indicators to glide seamlessly. With the quick improvement of electronics in varying industries which includes car, aerospace, and scientific instruments, figuring out the intricacies of cord bonding science has under no circumstances been greater valuable.

In this entire instruction manual, we're going to delve into alternative aspects of wire bonding consisting of its methodologies, gadget, functions, reliability tests, and long term developments. By the cease of this newsletter, amtech micro processes you will have an intensive knowing of the wire bonding system and its magnitude in smooth electronics.

What is Wire Bonding?

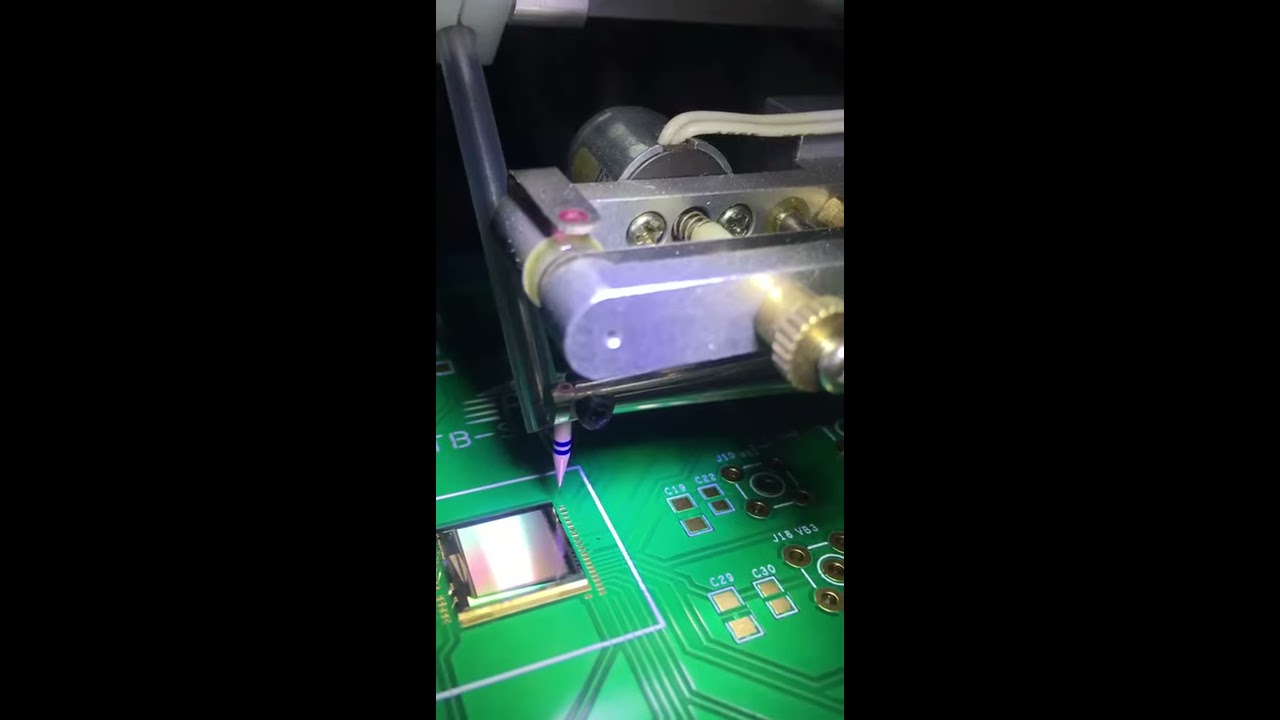

Wire bonding is a means used to create electric connections between semiconductor instruments and their programs or substrates by using first-class wires. The procedure mostly contains two normal systems: ball bonding and wedge bonding. Each process has its very own specific packages depending on causes like material homes and design requirements.

How Wire Bonding Works

Wire bonding employs mechanical rigidity and warmth to sort bonds between metallic wires—many times gold, aluminum, or copper—and pads on silicon chips or other surfaces. The collection of material continuously relies upon on rate considerations, thermal conductivity, and performance requirements.

Understanding the Wire Bonding Process: A Comprehensive Guide

The Importance of Wire Bonding Technology

Wire bonding know-how plays a pivotal position in ensuring official connections within electronic gadgets. As generation advances in opposition to miniaturization and higher complexity, helpful twine bonding solutions are critical for prime-efficiency programs.

Different Types of Wire Bonding Techniques

Ball Bonding- This approach contains growing a small ball on the finish of a twine by way of melting it with warmth earlier making contact with the bond pad.

- Wedge bonding makes use of a flat tool to press the cord opposed to the substrate without heating it.

- Ribbon bonding employs broader strips of metallic in preference to usual spherical wires for increased surface vicinity contact.

Wire Bonding Equipment: Key Components

- Wire Bonding Machine: The coronary heart of the operation the place automation takes location. Bonding Capillary Tool: Essential for positioning the wire effectively. Ultrasonic Generator: Supplies ultrasonic power in the time of detailed kinds of bonds.

Wire Bonding Applications Across Industries

Wire bonding finds use in a number sectors:

- Automotive Electronics: Ensures authentic connections in security strategies. Medical Devices: High reliability is paramount for existence-saving gadget. Aerospace: Components have got to withstand serious situations. Consumer Electronics: Mobile units require compact preparations.

Wire Bonding Failure Analysis

Understanding expertise failure modes is vital for recuperating reliability:

Oxidation Contamination Incomplete BondsCommon Failures in Wire Bonding

Failures can occur simply by bond lifting or heel cracks that compromise connectivity. Identifying these things early can ward off impressive losses down the line.

Wire Bonding Reliability Factors

Reliability is inspired with the aid of diverse reasons:

- Environmental controls Material choices Bond power calibration

Quality Control in Wire Bonding

Implementing stringent great keep an eye on measures ensures that each one bond meets market standards. Techniques like visual inspection or automated bond inspection play most important roles right here.

Cost Implications of Wire Bonding Processes

Understanding cord bonding expenditures can help services make counseled decisions on production:

- Material expenditures (gold vs aluminum) Labor costs linked to manual versus automated processes Maintenance charges for machinery

Comparative Analysis: Gold vs Aluminum Wire Bonding

| Factor | Gold Wire | Aluminum Wire | |---------------------|---------------------------|-----------------------------| | Cost | Higher | Lower | | Oxidation Resistance | Excellent | Moderate | | Thermal Conductivity | Superior | Good |

Best Practices in Wire Bond Design

Proper layout standards can improve reliability:

Use proper pad dimensions. Ensure fabulous loop top for tension distribution. Select fabulous supplies structured on application wants.Bond Strength Considerations

Achieving ultimate bond strength calls for careful calibration of parameters similar to pressure settings at some stage in utility.

Specialized Techniques in Wire Bonding

Advanced concepts embrace:

Micro Wedge Bonding Thermosonic Ball Bonding Deep Access Wedge BondingThese systems cater to targeted challenges posed by means of high-density designs.

FAQs approximately Wire Bonding

What ingredients are recurrently used in wire bonding?

Common constituents embrace gold, aluminum, copper, and silver by means of their awesome conductive houses.

How does environmental control have effects on wire bonding?

Proper environmental controls mitigate hazards reminiscent of oxidation or infection which could end in screw ups.

What industries benefit from wire bonding?

Industries like automotive, medical devices, aerospace, shopper electronics, and telecommunications all place confidence in solid cord bonds for function.

How do you carry out excellent control tests during cord bonding?

Quality checks may possibly involve visible inspections, automatic testing machines for bond integrity exams (shear checks), and x-ray inspections to become aware of hidden errors.

What is ribbon bonding? How does it vary from average ways?

Ribbon bonding makes use of wider strips in place of spherical wires allowing more effective floor arena contact which enhances reliability yet would require really expert kit.

Can I customize my wire bonding facilities?

Yes! Many suppliers offer customized answers tailor-made to unique mission necessities adding subject matter determination and layout standards.

Conclusion

In end, learning the complexities surrounding the twine bonding task is necessary for all and sundry involved in semiconductors or electronics production as of late. From determining proper material to knowing distinctive tactics like ball as opposed to wedge bonding—every detail contributes substantially to common product overall performance and reliability. Embracing inventions at the same time adhering to commonly used major practices will verify profitable outcomes across a lot of purposes.

By following this finished marketing consultant on Understanding the Wire Bonding Process: A Comprehensive Guide you now have quintessential insights into optimizing your operations at the same time as protecting high criteria all through your projects!