Introduction

In the ever-evolving panorama of electronics manufacturing, the desire for dependableremember and efficient bonding options has certainly not been extra extreme. The twine bonding procedure, an critical portion in semiconductor packaging, has seen noticeable advancements through the years. Among these options is thermosonic wedge bonding—one way that combines thermal and ultrasonic vigour to create solid bonds between wires and substrates. This article delves into the fine details of thermosonic wedge bonding, exploring its mechanics, reward, packages, and much more.

What is Wire Bonding?

Wire bonding is a pivotal procedure in electronics production that connects the die of a semiconductor to its package or substrate by tremendous wires. It is imperative to a number industries, which include telecommunications, car electronics, user units, and medical equipment.

How Wire Bonding Works

The cord bonding approach involves a few steps:

Types of Wire Bonding Techniques

- Ball Bonding: Typically used for gold cord; it creates a small ball at the give up of the twine sooner than making touch with the pad. Wedge Bonding: Utilizes a flat instrument to press towards the twine devoid of forming a ball. Ribbon Bonding: Involves wider wires that will join diverse pads simultaneously.

Applications of Wire Bonding

Wire bonding reveals functions throughout a lot of sectors:

- Semiconductor devices LEDs MEMS (Micro-Electro-Mechanical Systems) Power modules

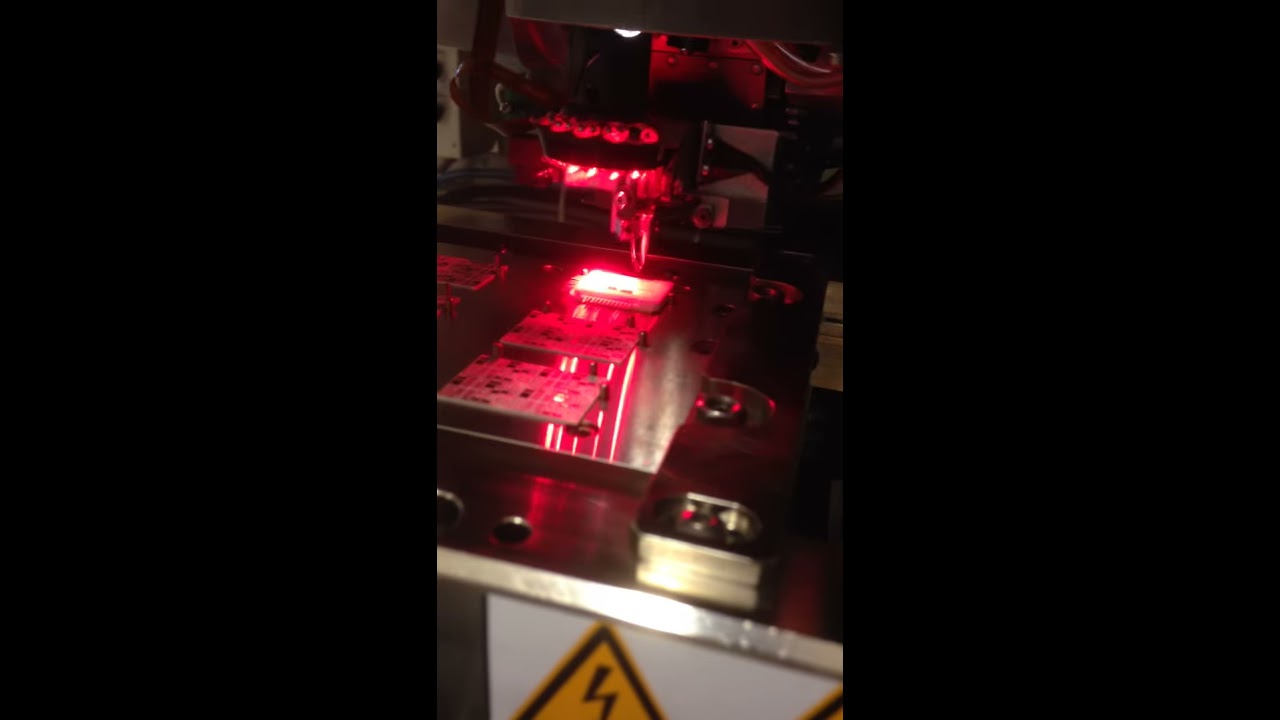

Understanding Thermosonic Wedge Bonding

Thermosonic wedge bonding represents a complicated kind of wire bonding that reinforces bond potential at the same time declaring reliability.

The Mechanics Behind Thermosonic Wedge Bonding

This procedure integrates either warmth and ultrasonic potential all over the bonding process:

Heat Generation: The thermosonic bonder applies localized warmth to soften the material being bonded. Ultrasonic Energy: Simultaneously, ultrasonic vibrations holiday down any oxide layers on the surface and facilitate intermetallic formation.Advantages of Thermosonic Wedge Bonding

- Improved Reliability: Ensures effective connections by lowering bond mess ups. Versatility: Suitable for several supplies like gold, aluminum, copper, and silver. Cost Efficiency: Reduces textile waste due to the more effective bonding precision.

Leveraging Thermosonic Wedge Bonding for Improved Bonds

When brands are searching for strategies to toughen their creation strategies, leveraging thermosonic wedge bonding proves useful. By making use of this generation, they could reap superior bond good quality at the same time minimizing bills associated with remodel or replacements.

Key Considerations for Implementation

Implementing thermosonic wedge bonding requires cautious consideration of several explanations:

Material Selection: Choose tremendous supplies based totally on conductivity and thermal homes. Equipment Calibration: Ensure that the thermosonic twine bonder settings are optimized for precise responsibilities. Environmental Controls: Maintain cleanroom conditions to hinder infection for the duration of production. more infoComparative Analysis: Wedge vs Ball Bonding Techniques

Many ask how thermosonic wedge bonding compares with classic ball bonding tools.

| Aspect | Wedge Bonding | Ball Bonding | |----------------------|---------------------------------------|---------------------------------------| | Equipment Cost | Generally lessen | Higher attributable to extra tooling | | Material Flexibility | Compatible with countless parts | Primarily proper for gold wires | | Process Speed | Faster in prime-extent functions | Slower owing to ball formation | | Reliability | Superior below rigidity | Good but varies with textile |

Wedge Bonding Applications in Semiconductors

Thermosonic wedge bonding has found out its vicinity within semiconductor fabrication strategies wherein reliability is paramount.

Use Cases in Semiconductor Packaging

High-frequency RF modules require specified connections which will withstand environmental stressors. Power electronics routinely make use of this procedure by means of its skill to handle better contemporary quite a bit with no degradation.Understanding Wire Bond Failure Analysis

Despite improvements in technologies like thermosonic wedge bonding, failures may nonetheless arise.

Common Wire Bond Failure Modes

- Bond Lifting: Occurs whilst inadequate pressure or temperature is carried out right through bonding. Heel Cracking: A fracture at the bond interface attributable to thermal pressure.

Failure Analysis Procedures

Visual Inspection X-ray Imaging Pull/shear testsFAQs approximately Thermosonic Wedge Bonding

1. What fabrics are simplest appropriate for thermosonic wedge bonding?

Thermosonic wedge bonding works well with gold, aluminum, copper, and silver wires due to the their conductive properties and compatibility with ultrasonic strength.

2. How does thermosonic wedge bonding expand reliability?

By combining warm and ultrasonic energy for the period of the activity, it produces more advantageous bonds whereas slicing failure rates related to oxide layers on surfaces.

3. Is thermosonic wedge bonding value-tremendous?

Yes! While preliminary apparatus charges should be would becould very well be bigger than regular systems, lengthy-term reductions come from diminished transform rates and accelerated yield.

4. Can thermosonic wedge bonds be utilized in prime-frequency packages?

Absolutely! They are fantastically efficient in RF modules wherein sign integrity is fundamental on account of their low resistance connections.

five. What are uncomplicated considerations encountered during twine bonding?

Common troubles embody incomplete bonds because of insufficient power settings or infection on surfaces most appropriate to bad adhesion pleasant.

6. Are there schooling classes a possibility for mastering wire bonding procedures?

Yes! Many trade organizations offer lessons ranging from amateur tutorials on twine bonding fundamentals up through complicated options including thermosonic wedge bonds.

Conclusion

In end, leveraging thermosonic wedge bonding represents a monstrous development in achieving stronger bonds inside digital units and semiconductor packaging methods. Its detailed aggregate of thermal control coupled with ultrasonic vigour now not basically complements bond reliability however additionally gives versatility throughout dissimilar material used in the present day in expertise production practices world wide!

As manufacturers preserve adapting their options towards more advantageous efficiency at the same time making certain quality outputs—thermosonic wedge-bonded connections will definitely play an more and more very important function relocating forward!

This accomplished booklet serves as a foundational useful resource well-applicable for engineers in search of insights into today's practices surrounding complex methodologies like Leveraging Thermosonic Wedge Bonding for Improved Bonds!