Introduction

In the world of electronics manufacturing, the cord bonding task plays a pivotal role in constructing risk-free electric connections among semiconductor chips and their substrates. As technologies advances, so does the complexity of wire bonding operations. This complexity necessitates rigorous high-quality keep an eye on measures to be certain that operational performance, product reliability, and consumer pleasure. This article delves into the intricacies of wire bonding era, exploring the diverse approaches, gadget, and functions even though emphasizing the significance of best management.

What is Wire Bonding?

Wire bonding refers to a collection of thoughts used to create electrical connections between semiconductor instruments driving skinny wires. These connections are predominant for making certain that electronic supplies functionality as intended. The cord bonding system encompasses a number of suggestions which include ball bonding, wedge bonding, and ribbon bonding, each with uncommon advantages adapted to extraordinary applications.

Types of Wire Bonding Techniques

Ball Bonding- Process: Involves growing a small ball at the conclusion of a twine because of heat and ultrasonic vigor prior to attaching it to a bond pad. Applications: Commonly used for gold cord bonding in microelectronics.

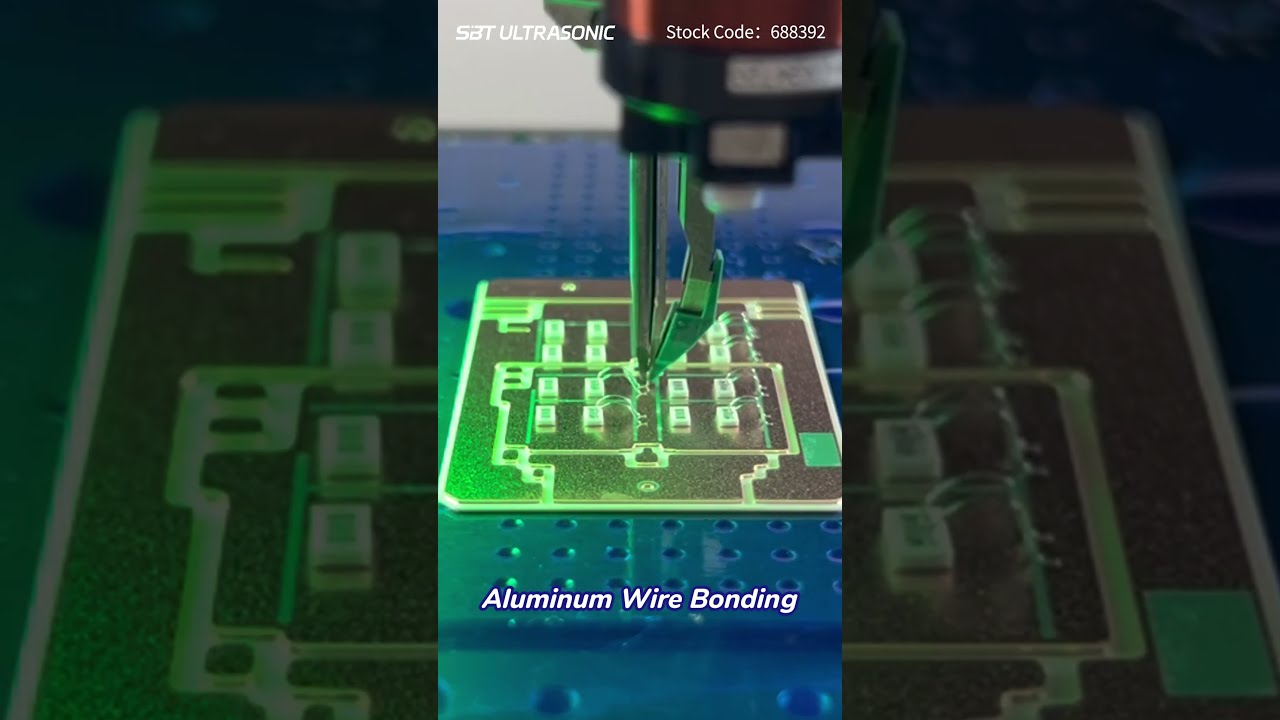

- Process: Utilizes a wedge-shaped software that presses the wire towards the substrate. Applications: Effective for aluminum and copper wires in high-frequency purposes.

- Process: Employs flat ribbons instead of around wires to establish connections. Applications: Ideal for drive modules via their expanded surface aspect.

- Combines heat and ultrasonic strength to beautify bond energy.

- Uses ultrasonic vibrations with out added heat for detailed supplies.

- Enables bonding in hard-to-succeed in regions inside not easy assemblies.

How Wire Bonding Works

The foremost theory in the back of twine bonding involves making use of pressure and heat (or ultrasonic strength) to affix metals as a result of metallurgical interconnections. It starts off with deciding upon impressive bonding wires—oftentimes gold, aluminum, or copper—based on their conductivity and mechanical properties.

Wire Bonding Equipment Overview

Wire Bonding Machines

Modern cord bonding operations be counted seriously on specialised machines tailor-made for distinct types of bonds:

- Manual Wire Bonding Machine: Designed for low-extent production; requires human operation. Semi-Automatic Wire Bonder: Offers partial automation to improve productivity when nevertheless requiring operator enter. Fully Automatic Wire Bonder: Ideal for top-extent creation; these machines can operate independently with minimum supervision.

Bonding Tools

Each machine is built with specified tools designed for superior overall performance:

- Bond Capillary Tool: Used to manipulate and function the wire in the course of bonding. Wedge Bonder Tool: Essential for reaching genuine placements in wedge bonding techniques.

Implementing Quality Control Measures in Wire Bonding Operations

Quality control plays a imperative function in making certain that wire bonds are reliable and meet market specifications. By imposing systematic QC measures throughout the wire bonding strategy, brands can tremendously cut down defects and amplify product efficiency.

Key Quality Control Techniques

Visual Inspection- Regular inspections deserve to be conducted to determine any visual defects comparable to bond lifting or incomplete bonds.

- Techniques like X-ray inspection allow brands to evaluate interior platforms with out damaging ingredients.

- Measures bond energy by applying a drive except failure occurs; facilitates assessment bond integrity.

- Similar to pull tests but specializes in horizontal shear forces performing at the bond interface.

- Maintaining controlled temperature and humidity phases during manufacturing can steer clear of oxidation-similar disasters.

- Regular calibration of machines guarantees consistent functionality across extraordinary batches of merchandise.

- Keeping thorough documents of each batch's parameters facilitates monitoring back any defects or worries that come up publish-production.

- Continuous instruction programs for operators about most excellent practices in caliber guarantee help mitigate human blunders for the time of operations.

- Establish partnerships with sturdy suppliers who adhere to strict cloth pleasant necessities reduces dangers related to inferior constituents.

FAQs

FAQ 1: What are regular problems encountered in cord bonding?

Common topics embody bond lifting, heel cracks, oxidation of bond pads, incomplete bonds, and infection for the period of manufacturing processes.

FAQ 2: How do you determine if a bond is strong enough?

Bond strength could be evaluated the usage of pull exams or shear exams wherein managed forces are utilized until failure happens; consequences wire bonding services suggest whether or not bonds meet required requirements.

FAQ 3: What elements are typically used for cord bonds?

Gold, aluminum, copper, and silver are extensively used supplies attributable to their accurate conductivity homes; choice mainly relies upon on software requisites like thermal control or money issues.

FAQ 4: Why is environmental manipulate great in wire bonding?

Proper environmental controls lend a hand mitigate dangers linked to moisture absorption and oxidation that may compromise bond integrity through the years; it truly is somewhat primary while running with touchy factors like MEMS or RF modules.

FAQ 5: Can I participate in manual inspections quite simply?

Yes! However, depending solely on visual inspection also can introduce variability by way of human mistakes; incorporating automated inspection platforms enhances accuracy considerably whilst featuring function assessments over timeframes imperative for upper quantity operations.

FAQ 6: What working towards assets are out there for discovering approximately wire bonding?

Numerous online courses exist masking the entirety from classic ideas of the way wire bonding works via superior topics like failure research; instructional papers posted by way of universities recurrently deliver insights into current research trends inside this area too!

Conclusion

Implementing Quality Control Measures in Wire Bonding Operations isn't really simply an practice yet an a must have side that defines success in digital production in these days. By concentrating on accomplished trying out methodologies blended with physically powerful operational protocols—alongside ongoing preparation tasks—enterprises can develop their production competencies when minimizing risk reasons associated with bad-high-quality connections made due to unreliable techniques or technologies on hand handy!

As we continue progressing closer to an increasing number of problematic digital designs pushing obstacles forward—first-rate warranty is still paramount! Thus making an investment time into realizing these strategies will yield dividends down line—now not simply financially yet additionally acceptance-shrewd amongst peers within this dynamic market region!