Introduction

In the evolving world of electronics, the alternative of materials plays a pivotal role in deciding the efficiency and reliability of devices. Among loads of interconnection methods, twine bonding stands proud as a vital technique used to determine electrical connections within semiconductor programs and other digital resources. This article delves into an in-intensity contrast among copper and silver cord bonding, exploring their houses, reward, dangers, and applications. By the give up of this comprehensive advisor, you'll be able to have a clearer expertise of which wire bonding process is excellent for your exceptional desires.

Copper vs Silver Wire Bonding: Which is Right for You?

The debate surrounding copper vs silver wire bonding has been ongoing in the semiconductor market. Each material promises amazing blessings and downsides, affecting all the pieces from expense to functionality.

What is Wire Bonding?

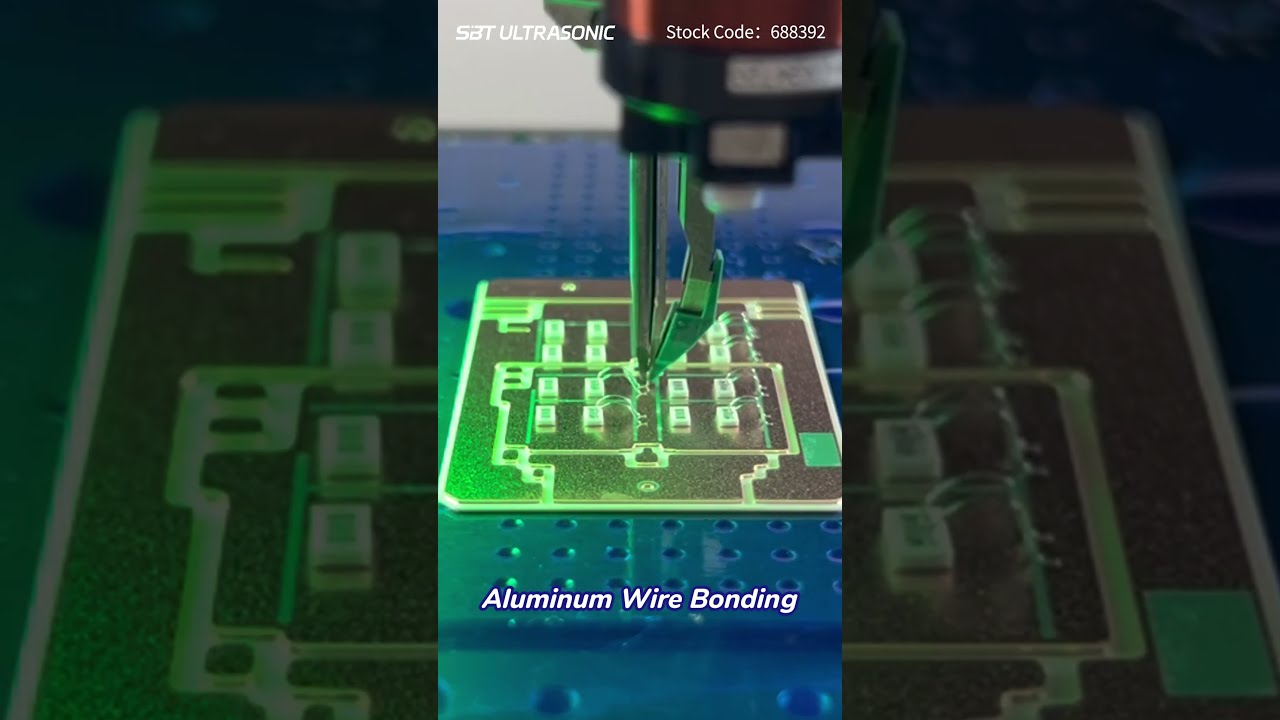

au ball wire bondingWire bonding is a greatly followed system used to create electrical interconnections among semiconductor instruments and their packaging. It includes the use of first-class wires—normally made of gold, aluminum, copper, or silver—to glue bond pads on incorporated circuits (ICs) to external leads or substrates.

How Wire Bonding Works

During the wire bonding activity, a skinny steel wire is connected at one finish to a pad at the semiconductor die with the aid of heat and pressure. The other end is then bonded to a lead frame or substrate the usage of an identical systems. The two primary types of bond processes are thermosonic and ultrasonic bonding.

Understanding Wire Bonding Technology

Types of Wire Bonding Techniques

- Ball Bonding: This manner employs an electrically heated ball-formed tip that paperwork a bond among the wire and pad. Wedge Bonding: In this manner, a wedge-shaped instrument applies rigidity at the same time ultrasonic calories allows create a bond. Ribbon Bonding: Utilizes flat ribbon wires instead of circular ones for elevated floor location touch.

Wire Bonding Equipment Overview

To perform twine bonding effectually, specialised kit including automated twine bonders and guide setups are utilized. Each laptop varies in capability and application based on manufacturing extent necessities.

Copper Wire Bonding: Advantages & Applications

Properties of Copper Wire

Copper boasts top electric conductivity and thermal residences, making it terrifi for top-efficiency functions. Its tensile electricity also lets in for exceptional pitch designs.

Advantages of Copper Wire Bonding

Cost-Effectiveness: Copper wires are ordinarily less highly-priced than gold or silver opportunities. High Electrical Conductivity: Ensures powerful sign transmission. Robustness: Suitable for varying environmental circumstances.Applications in Electronics

- Power modules Automotive electronics Aerospace applications

Silver Wire Bonding: Advantages & Applications

Properties of Silver Wire

Silver good points premier conductivity in contrast to both copper and gold. It’s specially high-quality in excessive-frequency applications owing to its cut down resistivity.

Advantages of Silver Wire Bonding

Superior Conductivity: Offers useful performance in high-frequency circuits. Corrosion Resistance: Less liable to environmental degradation than copper. Better Performance in Harsh Environments: Ideal for aerospace and medical units.Applications in Electronics

- RF modules High-vigour applications LED manufacturing

Comparative Analysis: Copper vs Silver Wire Bonding

| Feature | Copper | Silver | |--------------------------|----------------------------|-----------------------------| | Cost | Lower | Higher | | Conductivity | Good | Excellent | | Corrosion Resistance | Moderate | High | | Strength | High | Moderate | | Thermal Conductivity | Good | Excellent |

Factors Influencing Your Choice Between Copper vs Silver Wire Bonding

When opting for between copper and silver wire bonding ways, take into consideration points like:

Electrical Requirements: What stage of conductivity do you want? Cost Constraints: Are you running within a tight budget? Application Environment: Will your product be exposed to harsh stipulations? Long-term Reliability: How fundamental is sturdiness for your software?Wire Bond Quality Control Measures

Maintaining fine right through the twine bonding strategy is imperative for ensuring gadget reliability:

Monitoring bond capability with the aid of pull checks. Visual inspections to hit upon defects resembling heel cracks or incomplete bonds. Employing computerized inspection tactics to make sure consistency.Wire Bond Failure Analysis Techniques

Understanding capacity failure modes can aid mitigate negative aspects:

- Common failure factors comprise oxidation at bond sites, illness right through production strategies, and fallacious bonding tactics. Employ non-adverse checking out tips like X-ray inspection to recognize subject matters early on.

Conclusion

In end, the two copper and silver twine bonding tactics have their very own merits and obstacles relying on definite standards with regards to fee, performance, ambiance, and application sort. Evaluating these explanations sparsely will support make sure which strategy ideally suited matches your desires—even if you lean in opposition t check-beneficial copper suggestions or elect prime-efficiency silver possible choices.

Frequently Asked Questions (FAQs)

What are the major modifications among copper and silver cord bonding?- The major adjustments lie in rate-effectiveness (copper being less expensive), conductivity (silver being preferable), corrosion resistance (silver has superior resistance), and mechanical houses (copper basically offers bigger tensile energy).

- Industries like automotive electronics, aerospace functions, LED production, RF communications, energy modules manufacturing utilize numerous different types of wire bonding generation notably.

- Factors including utility surroundings prerequisites (temperature changes), preferred electric residences (conductivity standards), finances constraints (rate issues), and creation amount must always aid your resolution-making course of with regards to which method is right.

- Common disasters contain incomplete bonds due to insufficient force or vigor utilized all the way through processing; oxide formations at bond surfaces foremost to vulnerable connections; infection throughout meeting impacting adhesion high-quality; among others.

- Transitioning from one subject material (like gold) closer to some other choice requires cautious attention on the topic of compatibility with present procedures/strategies even though assessing performance affects that might occur from differences made for the time of production runs.

6. What assets can help additional my information about superior facets related peculiarly towards completely different varieties/kinds discovered within this discipline?

- For those eager newbies in the hunt for deeper insights into exceptional methodologies used inside this container may well find significance attending webinars hosted by way of market professionals alongside academic investigation papers possible on-line focusing especially upon issues linked instantly with a large number of sub-disciplines fundamental towards contemporary-day electronics design/production practices.*

This accomplished article serves as an in depth aid on "Copper vs Silver Wire Bonding" even though addressing realistic concerns principal throughout varied technical dimensions!