In the area of electronics production, twine bonding is a vital course of that connects built-in circuits (ICs) to their substrates or programs. This process not merely serves as a elementary step in semiconductor equipment fabrication, however it additionally performs a indispensable function in making sure reliability and overall performance of instruments. Among diverse elements used for cord bonding, gold and aluminum are the such a lot trendy options. But how do those two materials stack up opposed to every different? In this text, we will delve deep into the Comparing Gold vs Aluminum within the Wire Bonding Process, exploring their residences, benefits, dangers, and applications.

Understanding the Wire Bonding Process

What is Wire Bonding?

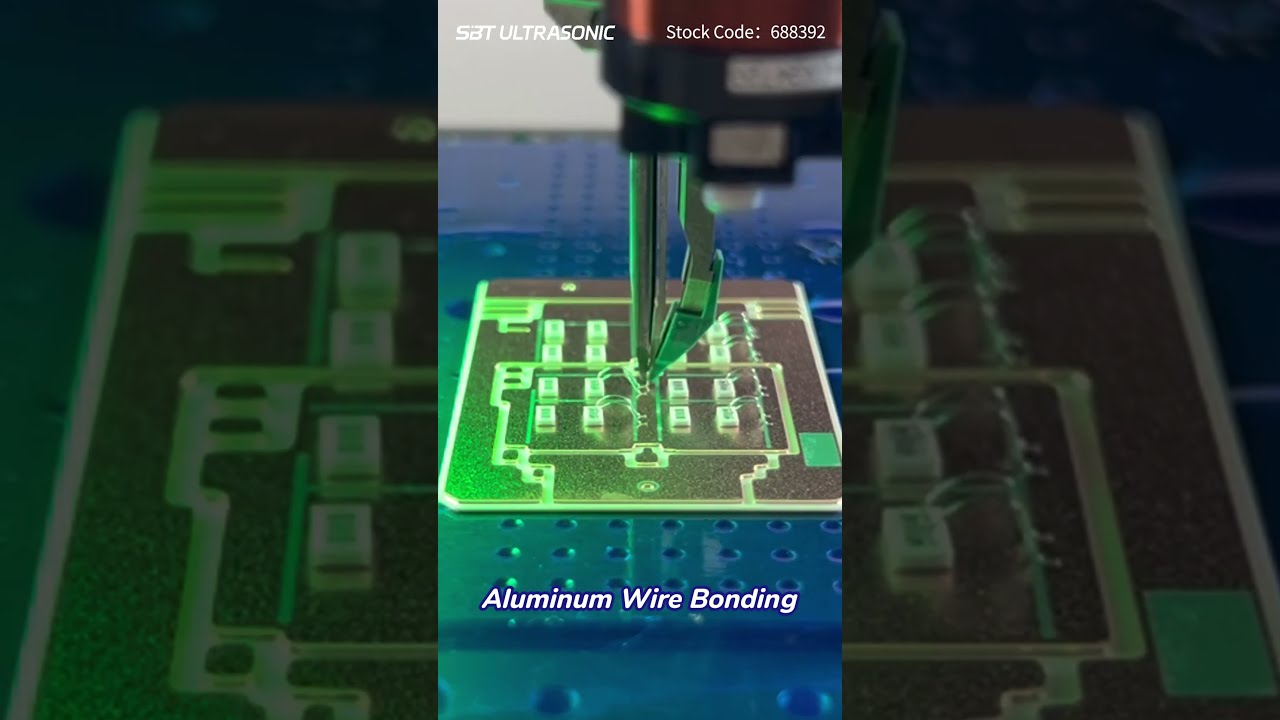

Wire bonding is a method that includes creating electric connections between semiconductor chips and their applications or substrates utilising first-class wires. The wires are usually constructed from metals such as gold, aluminum, copper, or silver. The task can also be finished by a number of options along with ball bonding and wedge bonding.

How Wire Bonding Works

The cord bonding activity largely comes to three predominant steps: bonding, loop formation, and tail trimming. An ultrasonic or thermosonic power resource is often employed to create potent steel bonds at increased temperatures.

Types of Wire Bonding Techniques

Ball Bonding: Utilizes a ball-fashioned quit on the wire. Wedge Bonding: Employs a wedge-fashioned instrument for making connections. Ribbon Bonding: Uses flat ribbons other than spherical wires for top-speed packages.Properties of Gold in Wire Bonding

Advantages of Gold Wire Bonding

Gold has pretty much been favorite through numerous qualities:

- Corrosion Resistance: Gold does not oxidize actually, making sure long-time period reliability. Excellent Conductivity: It grants surest electric conductivity in comparison to other metals. Ductility: Gold would be drawn into very thin wires devoid of breaking.

Disadvantages of Gold Wire Bonding

However, there are downsides:

- Cost: Gold is particularly extra expensive than aluminum or copper. Softness: While ductile, gold might also be extremely delicate, which may cause put on under specified circumstances.

Properties of Aluminum in Wire Bonding

Advantages of Aluminum Wire Bonding

Aluminum has received fame for several causes:

- Cost-Effectiveness: Aluminum is appreciably inexpensive than gold. Lightweight: It presents weight financial savings in packages the place mass is principal. Sufficient Performance: For many functions, aluminum's performance is ok.

Disadvantages of Aluminum Wire Bonding

Nonetheless, it has a few boundaries:

- Oxidation Issues: Aluminum effectively bureaucracy an oxide layer which could affect bond pleasant if now not accurately managed. Less Ductility: Compared to gold, aluminum wires are less ductile and will ruin all over processing.

Comparative Analysis of Gold vs Aluminum inside the Wire Bonding Process

Cost Comparison

When due to the fact wire bonding expense components: | Material | Average Cost in line with Kg | |----------|---------------------| | Gold | $60 - $70 | | Aluminum | $2 - $3 |

As illustrated above, aluminum sticks out as a miles extra reasonably priced choice than gold.

Reliability and Performance

Reliability is paramount in cord bonding applications:

- Gold Bonds generally tend to have better sturdiness using their corrosion resistance. Conversely, at the same time as aluminum can perform neatly below managed situations, its susceptibility to oxidation poses dangers for long-time period reliability.

Applications in Semiconductors

Both elements to find various makes use of inside semiconductor expertise:

- Gold wire bonding is usally implemented in excessive-performance purposes like RF modules and aerospace electronics. Aluminum unearths want in automobile electronics using cost efficiency.

Wire Bond Quality Control

To ensure surest functionality in the cord bonding course of:

Regular inspections by using computerized bond inspection package lend a hand title troubles early on. Various exams comparable to bond pull assessments and shear tests make sure bond capability and integrity.Wire Bond Failure Analysis

Understanding practicable failure modes is basic for recuperating reliability:

Bond Lifting: Often effects from negative adhesion for the period of the initial bonding section. Heel Cracking: Commonly found with brittle constituents; it takes place when rigidity concentrates on the bond interface.Implementing rigorous trying out concepts like JEDEC guarantees compliance with industry norms.

Conclusion on Comparing Gold vs Aluminum within the Wire Bonding Process

In summary, deciding upon among gold and aluminum for twine bonding boils down to utility requirements and payment issues. While gold can provide unheard of reliability and conductivity perfect for prime-end programs, aluminum provides a doable preference for price-sensitive projects devoid of extensively compromising efficiency. As technologies advances, either material will maintain to play a must have roles throughout loads of sectors — from microelectronics to automobile tactics — underscoring their significance in modern day electronic layout.

FAQ Section

1. What are the time-honored adjustments among gold and aluminum wire bonding?

Gold affords more desirable conductivity and corrosion resistance but at a greater price when put next to aluminum that's more not pricey yet liable to oxidation Visit this website troubles.

2. Can aluminum be used effortlessly in high-frequency functions?

Yes! While mainly less in style than gold for high-frequency applications as a result of oxidation matters, developments have allowed aluminum's useful use less than distinct circumstances.

three. Is it you'll to switch from gold to aluminum cord devoid of compromising reliability?

Switching elements need to contain thorough checking out considering the fact that special thermal enlargement charges may just impact bond integrity over time.

4. How do environmental explanations influence cord bond pleasant?

Humidity and temperature can significantly impression oxidation fees and for this reason affect total bond quality; hence environmental controls are crucial throughout the time of manufacturing strategies.

five. Are there any selections to gold and aluminum in wire bonding?

Yes! Copper and silver also are used; though they come with their personal set of challenges together with oxidation (for copper) or costs (for silver).

6. What role does guidance play in effective wire bonding methods?

Proper practise ensures that operators keep in mind nuances associated with subject material handling together with computing device settings which lastly leads to more advantageous yield quotes throughout production cycles.

By on account that all points highlighted above – from charges associated with every one cloth fashion by means of workable failure evaluation – brands can make trained selections that align with their operational wants at the same time as maximizing product efficacy inside aggressive markets!